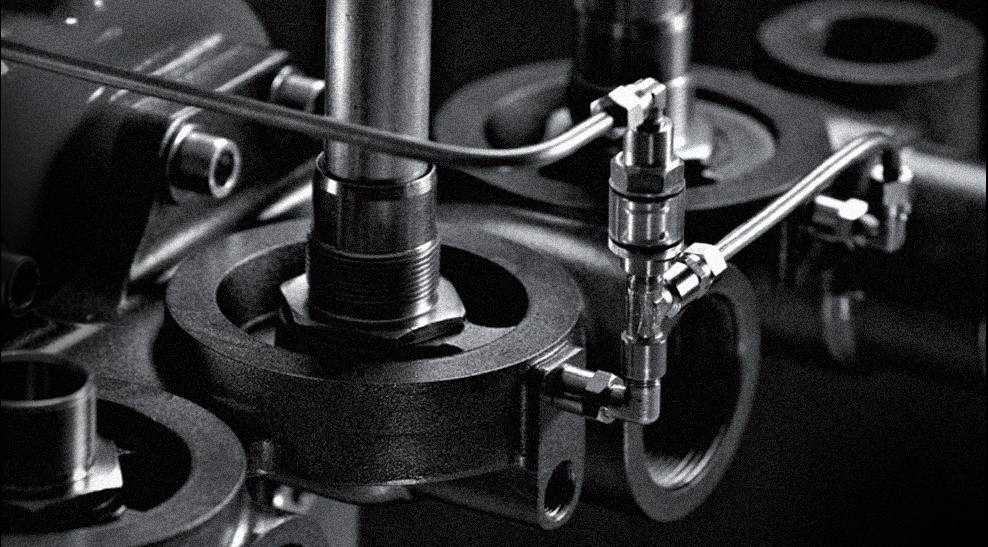

Encapsulated screw compressor

RIDING OVER STANDARD PERFORMANCE

Encapsulated Screw Compressor is the best expression of integration and technological optimization that VMC can offer on the compressor market.

Synthesizing all the advantages of a problem-solving philosophy, VMC heralds a universal range of products/solutions for each customer’s specific need.

That’s why all the innovative companies in the field rely on VMC’s Encapsulated Screw Compressor.

10 Excellent reasons to choose an ENCAPSULATED SCREW COMPRESSOR. Discover them now

- Cost-effectiveness and engineering time-reduction

- Just one part number for all components

- Pursuant to NORM2006/42/CE and PED RULE 97/23/CEAND ASME. ASME U STAMP and ASME UM STAMP

- First-rate de-oiling system(‹ 2 ppm) thanks to the innovative and extremely efficient patent

- User-friendliness and assembly speed on a compressor: you just need a few screws to fix an encapsulated screw compressor to a machine

- Contained overall dimensions thanks to a simple and compact design

- High accessibility. All to-be-maintained components are located in the right position for easy and fast replacement

- Testing. Each encapsulated screw compressor undergoes a test with the purpose of guaranteeing the utmost reliability and safety

- High performance. Reduced connections and almost non-existent piping system. This means fewer loading losses and energy saving

- Great flexibility and wide variety of combinations. Avaible direct or belt-driven with on-off version, proportional for stationary compressors and portable compressors besides offering a top-notch range of options as temperatures, operating pressures, voltages, certifications.

| Model | Power | Drive | Air Capacity (Iso 1217 Annex B 1996) |

Oil-injected quantity | Max Main rotor speed | Working pressure range |

|||

|---|---|---|---|---|---|---|---|---|---|

| Kw | hp | m3/min | cfm | l/min gal/min (US) |

rpm | barg | psig | ||

| V60 | 2,2-7,5 | 3-10 |

belt* |

0,28-0,97 | 10-34 | 11 - 15 2,9 - 4 |

7500 | 5-13 | 73-189 |

| V75 | 7,5-15 | 10-20 |

belt* |

0,65-2,1 | 23-74 | 20 - 28 5,3-7,4 |

7500 | 5-13 | 73-189 |

| V90 | 7,5-22 | 10-30 |

belt* |

0,763,83 | 27-135 | 29-40 7,7-10,5 |

7500 | 5-13 | 73-189 |

| V110 | 18,5-37 | 25-50 |

belt* |

0,86-6 | 31-212 | 50 - 70 13,2 - 18,5 |

6000 | 5-13 | 73-189 |

| V130 | 22-45 | 30-60 |

belt* |

2,2-8,4 | 78-297 | 57 - 80 15 - 21 |

5000 | 5-13 | 73-189 |

| V150 | 37-75 | 50-100 |

belt* |

2,6-13 | 92-459 | 75 - 105 20 - 28 |

5600 | 5-13 | 73-189 |

*Air-ends, Integrated and Pack Smart Systems can be supplied with relative direct-driven kit (Bell housing + spider couplings)